Many people keep tools in a garage, and if you like in a place where heating is a thing, steel tools are almost always going to develop rust in a location like this.

Question: How can I stop my tools from rusting in their toolbox? They never get wet and I keep the lid closed, but somehow rusting happens each winter. Summer is no problem, but winter always is. What’s going on?

Answer: We get wide swings in temperature where I live in Canada, with deep cold each winter. The rusting you’re experiencing typically happens in the spring, when garage temperatures warm up after a cold spell, it causes condensation to develop on the cold tools in the same way it does on a cold drink during summer. And a little moisture is all it takes to trigger rust. So your tools are getting wet after all, it’s just that the source of moisture is the air not some spilled or leaked source of liquid moisture.

I struggled with the problem of winter rust on tools at my own place, until I figured out the two secrets for fixing it. First, you need some kind of sealed toolbox to store tools; and second, some way to make the inside of that tool box drier than it normally is.

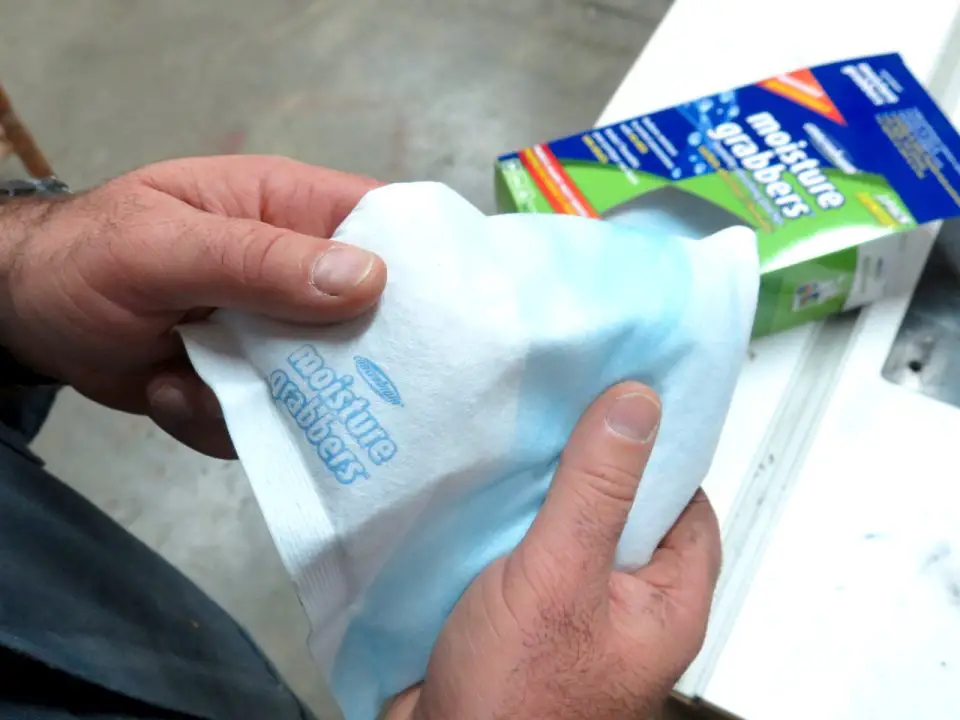

Start with a weatherproof toolbox of the kind that has a rubber seal around a tight-fitting lid. Stanley makes great tool boxes of this kind. That’s what you see above. Next, get a desiccant to put inside the box. This is a cloth pouch or canister of moisture-hungry granules that pulls water out of the air. One of the most widely available desiccants happens to be Canadian. Moisture Grabbers come in large and small pouches. One will keep the largest toolbox bone dry all winter long, with no tool rusting.

Eventually every pouch or canister will get saturated with moisture and won’t absorb any more. But both can be “recharged” by drying them out in a toaster over set at a low temperature. 120ºF for 30 minutes usually does the job.

This get more challenging if you have a table saw or other stationary tools in your garage, because you can’t put them in a dry toolbox. One option (not ideal, but very helpful), involves keeping rust-prone parts of these tools lightly oiled, especially just before spring. If some of these tools are already rusty, use a random orbit sander with a 120-grit disk to clean them. As for oiling, squirt a bit of 3-in-1 oil on the surface, wipe it around, then wipe off all you can. The thin film of remaining oil won’t affect tool useage, but it will protect against rust for about 6 months.

Heating your garage space will also eliminate tool rusting. If the tools never get cold, they won’t trigger condensation when things begin to warm up in the spring. That said, heating a garage involves significant expense, but you don’t need a lot of heat for success.