0:00

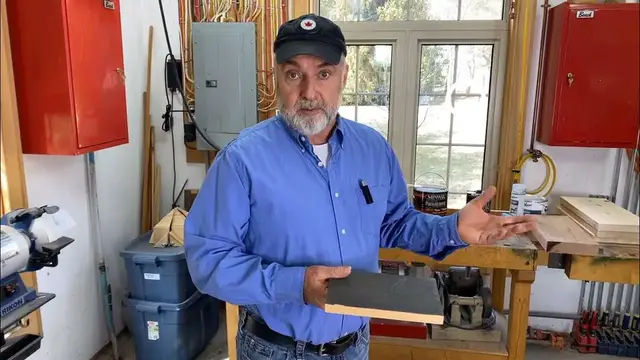

In this video I want to talk to you about staining. Now that's a process where you

0:06

impart color to the wood, color that wasn't there already, and you can see a

0:10

bunch of stained things. Everything is stained here except this. So nowadays you can get all kinds of different colors as you can see, but the

0:22

staining I'm talking about and the staining that I'm going to show you how to do later on is entirely different from what people mean when they say I'm

0:30

going to stain my deck or I'm going to stain the outside of my wooden house. And

0:34

that usually does impart color too, but that's kind of another process. It's not

0:39

the same as this process. It's a much coarser process, so don't be confused by

0:43

that. Now I am NOT going to show you how to apply stain in this video. We're going

0:49

to do that later, but I just want to show you what you can expect and what it

0:54

looks like and some of the drawbacks to do with stain as well. So here we got a

0:59

bunch of different colors. This is sort of a traditional brown, nice and smooth

1:05

Now the smoothness comes from, in this case, polyurethane sealing, like the

1:11

stuff I've already shown you. Same for this. This is the top half of a

1:17

frame and panel door. I cut this so that I could use it as part of my

1:22

demonstrations for how to do cabinet making and things. Both this stain and

1:27

this stain were oil-based stains that are now under a sealing coat. All of

1:33

these stains are water-based stains, so they're a little nicer to use. They're a

1:38

little safer to use, and you can get, as I said, a wide range of colors as you can

1:44

see here. Now the first thing I want to point out is that staining on its own

1:51

for interior work doesn't really make wood look all that good. I mean, take

1:57

something like this for instance. It's shiny, it's got some depth to it, it's

2:01

attractive, it's nice to run your finger over. Well, this is the same sort of wood

2:06

and it's been stained, but stained only. And well, there's nothing really to write

2:13

home about that, is there? It doesn't feel nice either. It's just got a color to it

2:17

But even the color is not representative of what you're going to

2:21

see once this is under some sort of sealing coat. So for our purposes here

2:26

all stains, all traditional stains, will be applied underneath some kind of

2:33

sealing coat. And that could be urethane, maybe some wipe-on poly, something a

2:38

little easier to apply. Less protection, but easier to apply. And that really

2:43

brings out the color. So one thing to keep in mind is when you're deciding on

2:48

what stain to use and you want to maybe do some some test patches or something

2:52

somewhere, don't assess the results until you get some some sort of a sealing coat

2:56

on it. Now another thing about this, and I hope you can see it, staining brings out

3:04

imperfections in the wood. Imperfections that you can't normally see. And you

3:09

can see what I'm talking about here. If you look closely, you'll see that there's

3:14

kind of some swirl marks. You see that? It's not too attractive. And you know the

3:20

swirl marks wouldn't go away after I apply urethane either. This is caused by

3:27

the use of a random orbit sander with a fair amount of hand pressure. This did

3:33

not look bad before I put the stain on. But stain brings out imperfections. So

3:40

that's something you need to keep in mind. If you're going to be staining

3:44

something, the sanding job really needs to be quite well done. And you need to

3:49

examine it closely to make sure that you don't have any scratches or swirl marks

3:54

There's another another thing you need to watch for, and that's any area where

4:00

the glue has touched the wood. Because even if you wipe the glue off, the

4:06

surface is still sealed. Which means that when you go to put stain on, the stain is

4:11

going to soak in all around that glue patch. But where the glue was, it won't

4:15

soak in. And so you're going to have a very light area. You might not even

4:21

notice it at first, but it's going to stand right out when you start your

4:24

finishing. In cases like that, you're going to want to take the time to sand

4:29

that spot or maybe use a little chisel or a scraper or something like that to

4:33

get the residual glue out. And it's not just glue on the surface either. It's

4:37

glue that affects the first few layers of wood cells. It's basically sealed

4:43

them ahead of time so that the stain can't soak in. So one other thing, when

4:50

you're making a decision about whether to stain wood or not, don't just consider

4:56

the appearance. You also need to consider durability. Because, I mean for

5:01

instance, this piece of wood here, urethane finish, no stain. If this was a

5:07

piece of furniture or even a floor or something like that, and we scratched

5:12

through this or we wore through the urethane, it wouldn't be the end of the

5:15

world. Because the wood underneath is pretty much the same color. It's just a little bit of yellowing that has happened here from the urethane. But if

5:23

you go through a dark stain and there's light wood underneath, it's really going

5:29

to show up and it's going to look ratty. You can go over with more stain again to

5:33

kind of hide that color difference. But you need to be aware of that. And this is

5:38

why sometimes it makes sense to finish as minimally as possible, to just seal

5:42

the wood and not to color it. Or if you're a woodworker, say, and you have

5:47

some control over the kind of wood you're finishing, then you might want to

5:51

choose a dark wood if you want a dark look. That way when you've sealed it with

5:56

a clear sealer that imparts no color, the dark wood is going to provide the

6:01

color for you. So even if you go through that urethane, no big deal because it's

6:06

still darker wood underneath. So that's staining in a nutshell. There's a little

6:10

bit more to talk about than this, but this will get us going