0:00

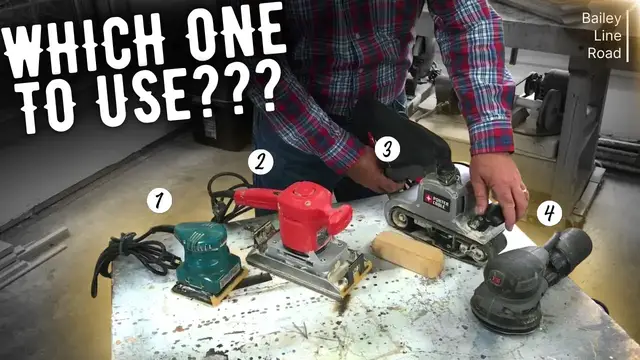

Sanding wood properly is a very big part of your success with any kind of

0:05

woodworking and especially cabinet making that we're talking about here. And part of that success comes down to using the right tools in the right way

0:14

So I use three different kinds of power sanders for my woodwork. If I have a lot

0:22

of material to remove I'm using a belt sander. A 100 grit belt is a great

0:29

all-around starting abrasive level. It's useful for softwoods and hardwoods and I use this when I have to level up panels or if I have a lot of mill marks

0:41

to remove. Now the next sander I like to use is this half sheet inline sander

0:48

Most of the movement of the pad here is back and forth so I can orient it in

0:56

relation to the grain and avoid cross-grain scratches. Now the avoidance of those kinds of scratches is one of the reasons why I definitely do not like

1:08

to use a random orbit sander on fine woodworking. This is a very common tool

1:13

for people to use but because of the action, the rotating action and then the

1:20

orbiting action together of the random orbit sander, that can leave cross-grain

1:25

scratches behind in your woodwork and it looks pretty bad especially after you've

1:32

stained it. You might not notice anything at first but the darker the stain the

1:37

more pronounced any cross-grain scratching will be. So that's why I like

1:41

to stick with the half sheet inline sander for what I would call

1:46

intermediate sanding. Sometimes you can use it on wood that's come from the

1:52

lumberyard if it's particularly smooth. You won't necessarily need to use the belt sander but this is a good intermediate level machine. This

2:01

quarter sheet finishing sander is what I like to use as the final machine

2:08

step. On pine or hardwood I would use a 180-220 grit abrasive. The inline sander

2:19

I like to use 120 and then I finish up with some 220, 180 or 220, used by hand in

2:28

the direction of the grain only. Now one other thing, this is a crepe rubber block

2:33

and it's extremely useful for getting the most out of your sanding belts. It

2:40

doesn't do very much to clean the abrasives on these tools but if you

2:45

start the machine and you hold the crepe rubber block in this orientation

2:51

so that the belt is moving this way and I'm holding the rubber block this way

2:56

it's going to do a fabulous job at getting out the sawdust and some resins

3:01

and really renewing the action of a belt. You can probably get twice the belt life

3:07

if you clean them with a crepe rubber block