- Video Watch Time = 3 1/2 minutes

Emotions drive people more than anything else, and this is why home improvement is so perennially popular. We all want our houses to make us feel good, and the three router-based ideas you’ll discover here can help make that happen. They create visual features that appeal to both the eyes and the heart, without adding significant costs or hassles to your construction or renovations schedule.

The Bullnose Profile

The semi-circular bullnose profile has been used traditionally for centuries, though it’s largely been forgotten in house trim since the 1940s. That’s good news for innovative builders and renovators because appealing to emotions always involves details that aren’t part of every new subdivision in town. You won’t find wide assortments of bullnose moulding from trim suppliers, but you can mill your own in a variety of sizes ranging from 3/16” to 1 1/2” in diameter with a portable router table, either onsite or in your home workshop. Big bullnose profiles also make sense on the edges of deck boards and deck railings. You can see what I mean below.

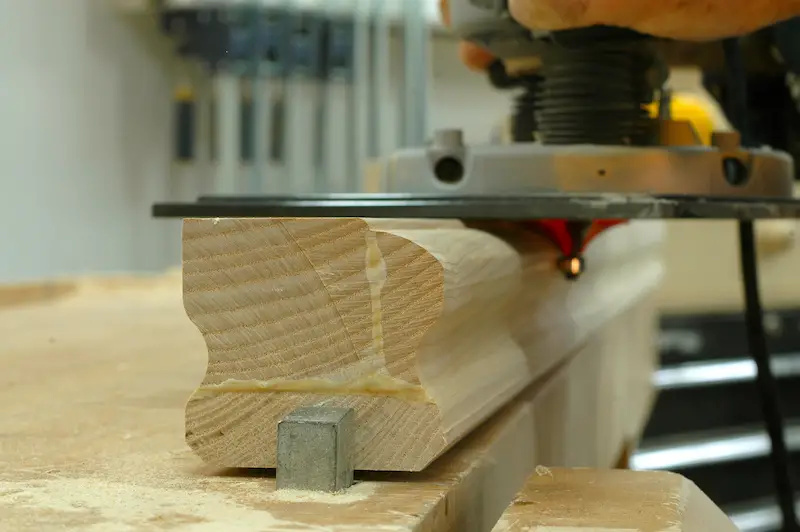

Mill Your Own Handrail

Ordinary hardwood handrail costs about $10 to $20 per foot, and then only in the same wood species and profiles that everyone else is using. Router bit technology now exists for producing full-size, custom staircase hand rails out of any kind of wood on the planet. Multiple passes across a 3” x 3” blank creates the rounded top edges, the finger grooves on the sides, and chamfers along the bottom that make for great railings. The same hand rail bits also make terrific shoe rails for the bottom parts of railings where spindles are anchored.

Click below and you can see the process of milling your own handrailing.

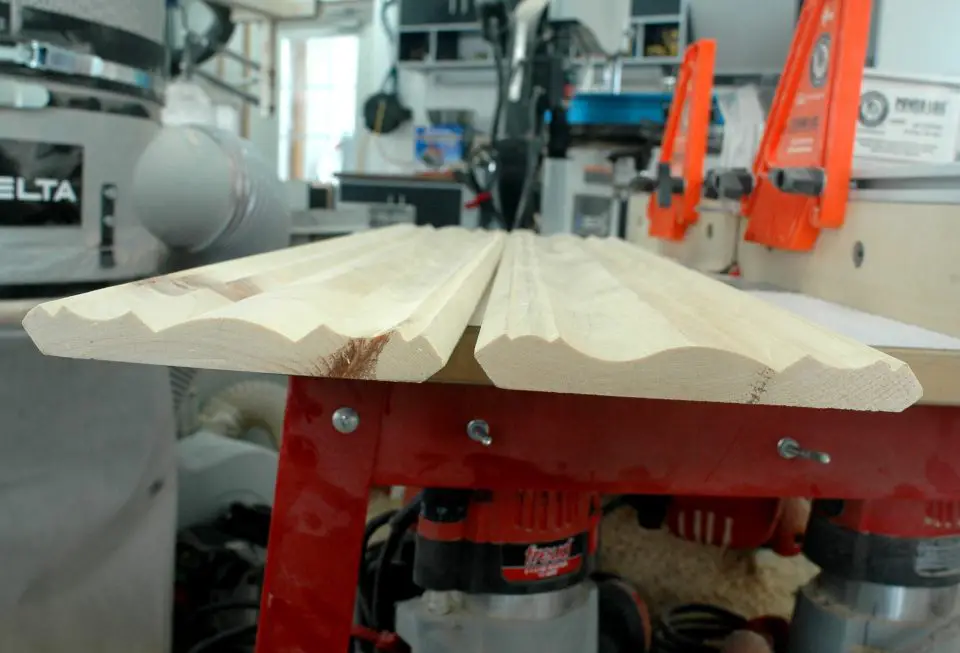

Routing Your Wide Crown Moulding

The same advantages offered by routing custom handrail also goes for making wide crown moulding. Sure, you can buy pine and oak crown off the rack, but for roughly the same total cost you can rout crown from cherry, walnut, ash or any exotic species up to 5 1/2” wide, beginning with simple, 3/4”-thick lumber. All it takes is a 2 1/2 hp or 3 1/4 hp router in a router table, along with a wide fence to support the wood on edge. The key is a milling system that uses two different router bits: one that creates half of the 5 1/2”-wide shape, and another bit that mills the other half in a second pass.

Click the image below for free plans-and-instructions download for building your own tall router table fence that’s ideal for milling crown molding.

People pay good money for homes that are durable, comfortable and practical, but as important as these sensible attributes are, logic alone has never been the most powerful way to move people. The difference between an ordinary house and a design that people fall in love with is often nothing more than the emotions conjured by several hundred feet of unique, attractive, custom-milled trim or moulding. Try it once, and you’ll never settle for ordinary again.