Wood isn’t the only material you can plane, rout, mill and join to create refined workshop projects. Composite lumber can also be used for fine “woodworking”, despite the fact that it’s designed for outdoor use supporting deck chairs, barbecues and people relaxing. Even though I’ve worked with composites for more than ten years – including the construction of simple outdoor furniture – I didn’t realize the full potential of composites until I was asked to tackle an unusual project.

Wood isn’t the only material you can plane, rout, mill and join to create refined workshop projects. Composite lumber can also be used for fine “woodworking”, despite the fact that it’s designed for outdoor use supporting deck chairs, barbecues and people relaxing. Even though I’ve worked with composites for more than ten years – including the construction of simple outdoor furniture – I didn’t realize the full potential of composites until I was asked to tackle an unusual project.

Two local Canadian heroes were being celebrated in a little town near my home, and the commemoration included a couple of engraved granite plaques. Trouble was, the 1/2”-thick stone was too thin to be drilled and mounted directly onto a building. Without a frame of some kind to support the plaques and provide a mounting surface for bolts, the granite would crack. Wood was suggested as a frame material, but I didn’t like that. If community volunteers ever neglected to maintain the wooden frames regularly over the years, it would weather, crack and turn grey. And is ratty wood any way to honour a person who’s received the Order of Canada? No, something completely maintenance-free was needed, and that’s what got me thinking about left-over Trex I’d stacked behind the shop.

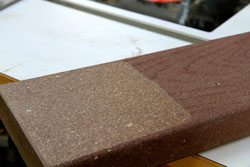

Trex is one of a handful of non-hollow composite materials made by various companies from a 50/50 blend of recycled plastic and wood fibers. The feedstock is typically plastic shopping bags and old wooden shipping pallets. The granite-like appearance of Trex proved to be a perfect complement to the actual granite of the engraved plaques, and I know from experience that composites weather well. Even after a decade of sun and weather, the only change is a slight fading of colour. But as durable as it is, it didn’t take long for me to discover that the slight warps and cups in each composite board would make any kind of fine craftsmanship impossible. Though irrelevant in a deck, this distortion is a deal breaker in finer work, until I discovered something new about composites.

Trex is one of a handful of non-hollow composite materials made by various companies from a 50/50 blend of recycled plastic and wood fibers. The feedstock is typically plastic shopping bags and old wooden shipping pallets. The granite-like appearance of Trex proved to be a perfect complement to the actual granite of the engraved plaques, and I know from experience that composites weather well. Even after a decade of sun and weather, the only change is a slight fading of colour. But as durable as it is, it didn’t take long for me to discover that the slight warps and cups in each composite board would make any kind of fine craftsmanship impossible. Though irrelevant in a deck, this distortion is a deal breaker in finer work, until I discovered something new about composites.

The same jointing, planing and routing operations that create the kind of smooth, flat, square wooden boards necessary for cabinets, tables and shelves, also work on composites. In fact, they work even better than on wood. Composites are so stable, consistent and machinable that they mill like a dream. There’s no melting of the plastic component while cutting, planing or routing, and it doesn’t seem to dull tools any faster than wood. After rough-cutting composite boards to length and width, the jointer did an astonishing job creating flat surfaces and square edges on formerly concave Trex boards. My thickness planer also milled the blanks down to perfect final thickness, though I was still left with a big question: How can I securely join outdoor materials that are 50% plastic in a high-stakes situation?

I knew that ordinary wood glue would never hold, but what about polyurethane adhesives? How about PVC cement? Construction adhesive? In the end, after trying several options, I settled on epoxy because it worked so well in my tests. I originally tried a five-minute formulation, and though it holds composite securely, I needed more assembly time. A four-hour epoxy proved perfect, and that’s what I used on the frames here. Just give it at least two or three days to cure. Try to sand off excess glue any sooner than that and it’ll clog up your abrasives way too fast.

I knew that ordinary wood glue would never hold, but what about polyurethane adhesives? How about PVC cement? Construction adhesive? In the end, after trying several options, I settled on epoxy because it worked so well in my tests. I originally tried a five-minute formulation, and though it holds composite securely, I needed more assembly time. A four-hour epoxy proved perfect, and that’s what I used on the frames here. Just give it at least two or three days to cure. Try to sand off excess glue any sooner than that and it’ll clog up your abrasives way too fast.

The cope-and-stile joinery I used for my frames needed nothing more than glue for a secure joint. My tests showed this for sure. Even bashing assembled test joints with a hammer could not break them apart. If your projects include butt joints and mitres, you’ll need to add some kind of mechanically interlocking connection like dowels or biscuits. Screw joints work fine for low-stress situations, and are easy to hide using tapered plugs made out of composite.

Once you realize that composites can be jointed, planed, milled and glued just like any wood, it becomes possible to build weather-tough display frames, boxes, birdhouses, cabinets, work surfaces and even fine outdoor furniture. Of course composites will never take the place of real wood, but they’re a pretty good alternative when water, weather and sun are working against you.