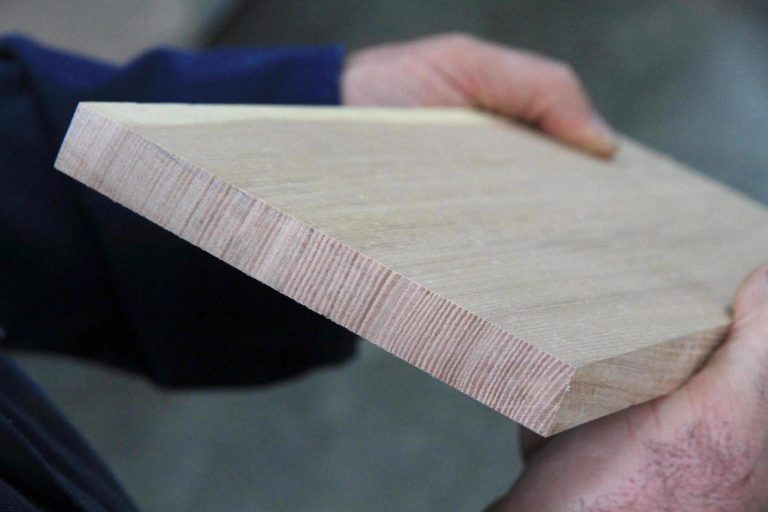

Dowel joints are one of the best ways to connect pieces of wood in the home workshop. They’re fast, low-tech, versatile, strong and invisible in the finished project. An unassembled dowel joint is what you see above. Drill matching holes across the joint area with the help of a jig; bring parts together with dowels and glue; clamp the joint tight. That’s the dowel-joining process in a nutshell, and thanks to a Canadian inventor, the possibilities for excellent dowel joints are bigger.

Jim Lindsay spent his career as a marine insurance investigator and home work shopper living in West Vancouver, Canada. He’s also the inventor of a patented tool called Dowelmax (1-877-986-9400). I’ve seen and used a handful of dowel jigs over the decades, but none are as versatile and accurate as this one. At about $250, the tool isn’t cheap, but it’s highly effective and beautiful — a combination that’s hard to resist. I find Jim’s tool development story fascinating because it combines unusual amounts of determination, skill and perseverance. And it all started with his first do-it-yourself woodworking projects, built out of necessity more than 40 years ago.

Joinery By Necessity

“When my wife, Marie, and I came to Canada from Scotland in 1974 with our two kids, we weren’t exactly well off. The crate containing our belongings was made of 1-inch thick pine that I carefully disassembled, making the wood into beds for the kids, end tables and small coffee tables. That began an interest in woodworking that continues to this day. I’ve since built 95% of the furniture in our home, and as I did this work I found myself searching for a kind of dowel jig that I never found. That’s why I decided to build my own.”

All dowel jigs are designed to guide the drilling of matching holes that house dowels installed across a woodworking joint. The dowels span the joint line, making the connection stronger than glue alone because of the mechanical connection they provide. Trouble is, the actual success rate of dowel joint installation varies a lot because few jigs are designed to operate as accurately as necessary for really terrific results. That’s been my experience and that of other woodworkers, too.

Dowelmax Caught My Eye for Two Reasons

- First, it boosts the accuracy of drilled holes so parts come together with piston-like precision.

- The jig also allows a closer and more varied arrangement of dowels than possible with other jigs.

It’s a unique combination.

Hendrik Varju is a custom furniture builder in Erin, Ontario, Canada. I’ve known him for many years and he uses a lot of dowel joints in his work. And it was his dissatisfaction with conventional dowel jigs that prompted him to buy a Dowelmax. I know Hendrik well, and he is an exceptionally particular woodworker.

“I have to say that I still felt a healthy dose of skepticism when I opened the box because of my experience with other dowel jigs”, said Hendrik. “But after using the unit for the first time on some hardwood, I was very impressed. I was actually able to close a multi-dowel joint by hand using only steady pressure and no clamps. Yet the fit was so snug that I had to struggle to separate the pieces.”

A Challenging Development

“Bringing Dowelmax from conception to market has been a daunting experience,” explains Jim. “The job encompassed the patenting process, prototyping the design, manufacture of the jig and marketing. My son, Mike, and I worked together to make this happen, and the whole thing took much longer than I first envisioned. It demanded deeper pockets than I thought, too. In our case, we decided to risk our retirement funds and bring Dowelmax to market without bank loans or investors. And that’s a do-it-yourself project of an entirely different kind.”

Dowelmax also happens to be a beautiful thing to look at, and that’s nothing to dismiss lightly. If you’re a tool person, you know how fit, finish and machined accuracy have a mesmerizing attraction all their own. So let me warn you. One look at this thing and you’ll probably end up convincing yourself that you really do need to include a whole lot more dowel joints into your projects.