- Video Watch Time = 10 minutes

I should have known better, but the wall-to-wall vinyl carpeting on the floor of my 1990 F150 had been holding moisture against the metal for years. I ripped the stuff off when I discovered it, but not before a hole had rusted through the floor. Watch how I use steel, my MIG welder and some autobody solder to fix this damage almost as good as new. If you’re tired of the drawbacks of catalyzed autobody filler (and there are many), this is the technique for you.

What Happened

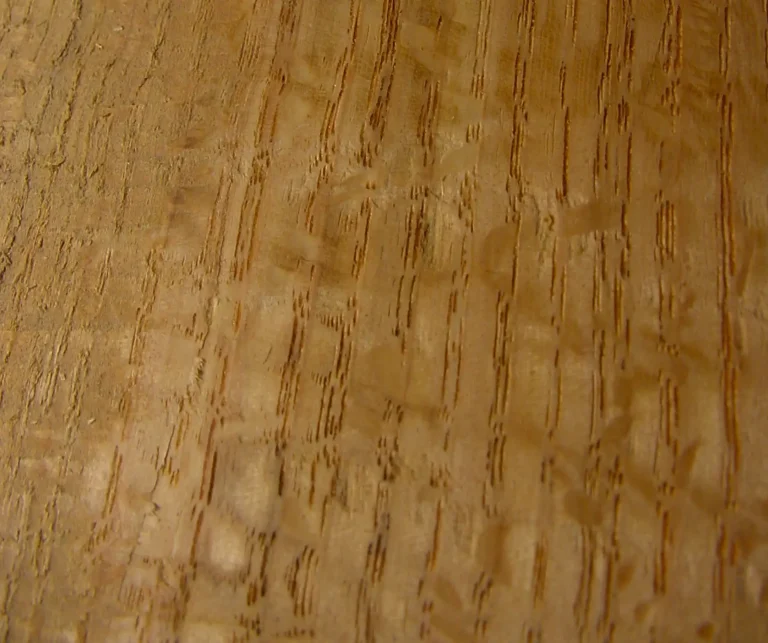

- Water became trapped under a wall-to-wall rubber mat

- Moisture caused rust on the driver’s side floor

- Several small pinholes developed

- One larger hole required a full metal patch

- Passenger side remained factory solid

The Repair Strategy

This is a 100% metal repair, not a body-filler patch.

The plan:

- Grind away rust to full-thickness steel

- Cut and shape a steel patch

- MIG weld the patch into place

- Grind welds flush

- Finish the surface using traditional body solder

No Bondo. No synthetic filler.

Why Use Body Solder Instead of Bondo?

- Solder is metal — not plastic filler

- Stronger and more durable

- Bonds chemically to steel

- Traditional auto body method used before body filler was invented

- Easier to shape than many people think

This is an old-school technique that still works beautifully.

Step-by-Step Overview

1. Remove Rust

- Grind to solid metal

- Eliminate feathered rust edges

- Prepare clean steel for welding

2. Fabricate the Patch

- Use sheet metal thick enough for strength

- Shape with aviation snips

- Test-fit carefully

- Remove surrounding paint for weld contact

3. MIG Weld in Place

- Spot weld around perimeter

- Protect wiring and trim with heat shields

- Grind welds flush

4. Apply Tinning Butter

- Flux + solder particles

- Chemically cleans surface

- Prepares steel for solder bonding

5. Add Body Solder

- Heat with propane torch

- Build surface slightly high

- Grind and shape smooth

- Add more solder if needed

6. Prime and Paint

- Sand smooth

- Prime

- Apply topcoat

- Repair becomes nearly invisible

Tools Used

- Angle grinder

- MIG welder

- Aviation snips

- Propane torch

- Body solder

- Tinning butter

- Wire brush

- Random orbit sander

Key Lessons

- Trapped moisture under rubber mats causes hidden rust

- Oil spray protection works — except where water is trapped

- Full-metal repair is stronger and longer lasting than filler

- Body solder is still a viable modern technique

- Careful prep makes all the difference

FAQ Section

Can you fix a rust hole in a truck floor without Bondo?

Yes. Cut out the rust, weld in new steel, and finish with body solder for an all-metal repair.

Is body solder better than body filler?

Much better. Body solder is stronger and bonds chemically to steel. It’s more durable but requires more skill. And unlike body filler, solder won’t encourage re-rusting.

What thickness metal should be used for a floor patch?

Thick enough to match factory strength but thin enough to cut and shape easily with snips. Exact thickness is not important.

Can MIG welding be used for sheet metal repair?

Yes. Short spot welds spaced closely prevent warping, overheating and burning through the metal.