Almost every basement I’ve seen has at least some cracks in floors and walls. Yours probably does, too. Most times these cracks are small and stable, and need filling only to prevent water and radon gas infiltration. Occasionally basement cracks are bad news because they’re caused by a foundation that’s slowly shifting and failing, but that’s not a common situation. So, how do you know if a basement crack is serious or insignificant? And, more importantly, exactly what should be done when you find cracks in your basement, especially when you have plans to finish the space? Something more than injection alone is what I want to explain here.

Jump to the video

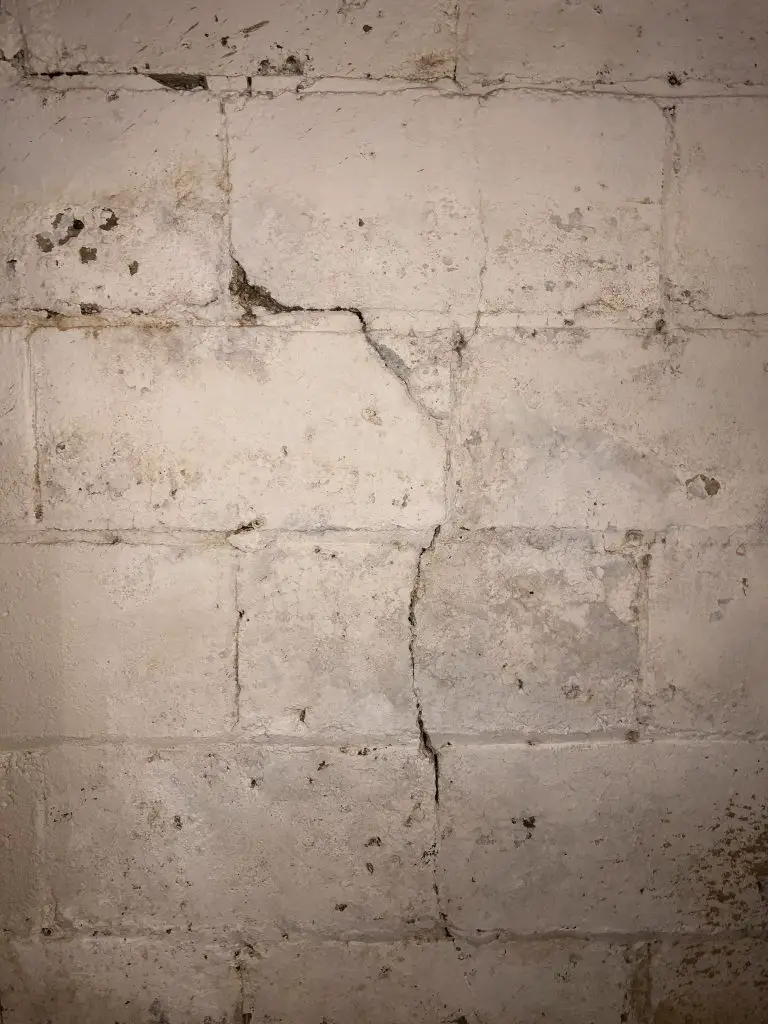

All basement cracks are caused by movement. Masonry walls and floors are rigid and inflexible, so if different parts of your foundation move independently of each other, cracks develop in response to this movement. It can take a few years for a new home to settle down and stop moving, so small and stable foundation cracks are most likely to appear early on. Hairline cracks, less than 1mm in width are probably fine. Even bigger cracks are absolutely fine if they don’t get any bigger over time, and that’s the first thing to determine. What is happening over time?

Use a sharp pencil and a ruler to draw a straight line across the crack. Do this at 90º every few feet, along with careful measurements of the width of the crack recorded next to these lines. Is this crack changing over time or is it stable? This is the key question.

If the cracks don’t change, you’re fine. But if cracks keep moving and getting bigger, or they’re horizontal, then you may have a problem that you’ll need professional help solving. Engineers and foundation specialists don’t come cheap, though. The wall you see here is a perfect example of the kind of situation where filling works best in conjunction with a layer of reinforcement added to the surface. You can learn more about foundation crack repair costs here.

Thankfully, the vast majority of basement cracks are stable and not serious, though it still makes sense to fill them. Why? Waterproofing and radon gas resistance, mostly. While it’s true that concrete blocks and poured concrete aren’t all that waterproof on their own, a crack that goes right through the foundation wall is not waterproof nor gas-proof at all.

Two-part epoxy or polyurethane injection systems are common methods for filling basement cracks, but they don’t provide structural reinforcement. Even an insignificant amount of new foundation shrinkage after filling can cause a new crack to appear alongside your injection, but that’s where a unique reinforced approach can help.

Of all the basement crack repair options I’ve researched for consumer use, a product called DRICORE Pro Concrete Repair is the best I’ve seen. This product impresses me most because it includes physical reinforcement in addition to injection. The kit comes with sheets of woven carbon fiber fabric made to bond to the concrete with epoxy and provide strength. This bonding won’t stabilize a foundation that’s got serious structural problems, but it is much more likely to provide a once-and-for-all stable crack repair than injection alone. DRICORE Pro Concrete Repair involves a three-step process.

The first step is to seal the surface of the crack and fasten injection ports every 18” or so along the length using a two-part epoxy. Once this epoxy has cured, the second step is to inject the crack, filling all voids to seal it. The final step is to apply carbon fibre saturated with epoxy over the crack to further stabilize the repair. The manufacturer claims the results are stronger than an uncracked foundation and I’m inclined to believe it based on my strength tests. If further foundation movement happens, it should never result in the old crack increasing in size. Carbon fiber is that tough.