Q: Is it possible to blow insulation into the wall cavities of one of those little veteran homes built right after WWII? I’m afraid to shop around for this work to be done because I don’t want to be taken advantage of.

A: Blowing loose-fill, fiber-based insulation into wall cavities is tricky because you never really know how congested those cavities are. The veteran houses I’ve seen are double brick construction with a small air space between the bricks, about 1″ wide. Does this sound like your home? If so, the challenge is two-fold. First, there’s not a lot of space between bricks in this kind of construction – only about an inch, as I said. This translates to only about R5 of insulation at the most, and even then only if you can get the space completely filled with insulation.

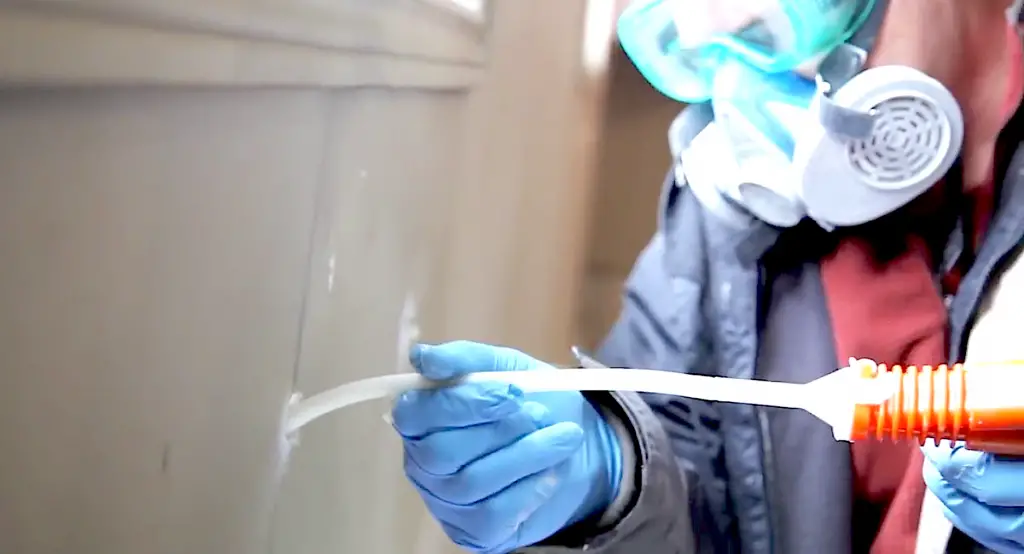

The second issue is the fact that blobs of hardened mortar are usually found between layers of brick, making it difficult to get consistent insulation flow through the space. The best approach I’ve seen does not use blown in fibres, but rather slow-rise expanding polyurethane foam injection along with an infrared camera to determine coverage.

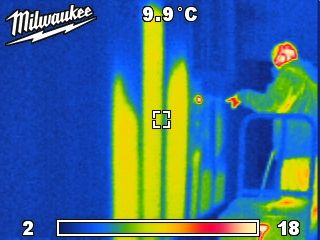

The best expanding foam gives off heat as it cures, so the infrared camera will show missed spots as being colder than areas that are warm because of the curing foam. That’s what you see below. Drill more holes through the drywall in cold zones and fill them with foam before moving on. The infrared photo below shows the same worker as above, but with the warm, fully-filled stud cavities shown plainly.

A better option than blowing or injection is to apply two inches of rigid expanded polystyrene sheet insulation to the interior face of exterior walls, followed by new drywall. This is a lot of trouble, yes, but it’s often the only way to make a practical difference.

Watch the vide below for a detailed tour of slow-rise foam injection into the wall cavities of a garage that was built with no insulation between studs. I think you’ll find this interesting.