If I had to choose one woodworking machine for hobby use or DIY renovations, a table saw would be it. This mainstay woodworking machine is especially useful, but you need to understand how to stay safe while using one.

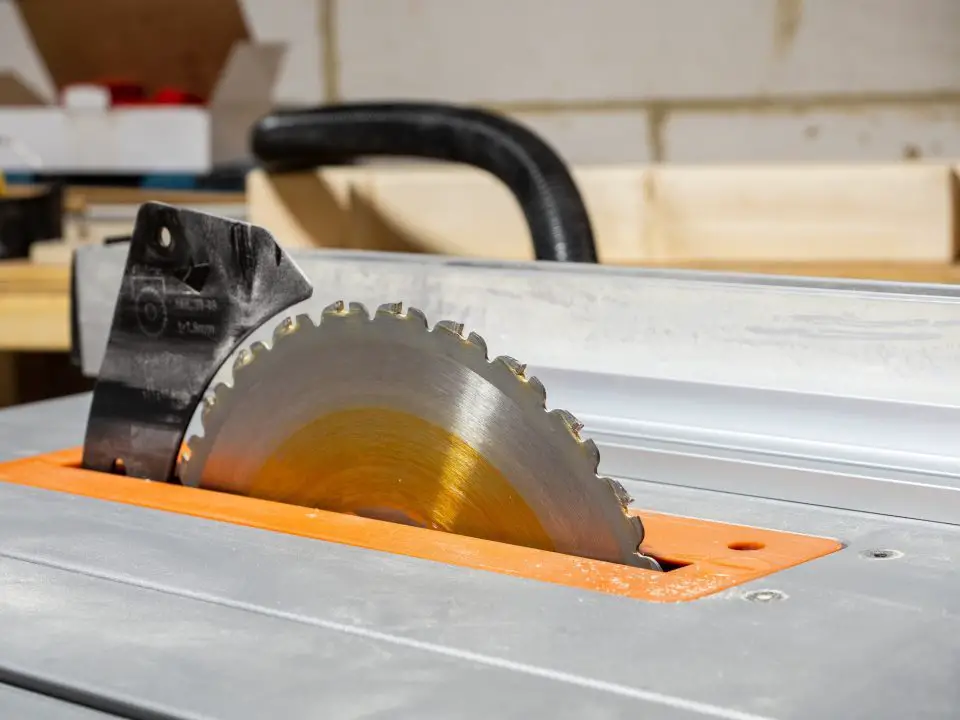

All table saws include a circular saw blade that extends up through a flat table surface for making straight, accurate cuts in wood or wood-like materials. Choosing and using a table saw safely comes down to understanding a few basics.

Types of Table Saws

Most handy homeowners find that bench top or contractor-type table saws are best. As the name suggests, bench top models are portable, light in weight (50 lbs. to 60 lbs.) and operate while sitting on a workbench or on a folding stand that comes with the saw. Contractor models are larger, heavier (150 lbs to 200 lbs) and come with a non-folding stand. They’re still portable, but not as easily as bench top models.

Table Saw Safety Basics

Begin by reading the manual that comes with each saw. Regardless of the type of table saw, there’s one safety precaution you always need to follow. Whenever you have your hands anywhere near the blade, always shut off the power to the saw, then test by trying to turn it ON to make sure it really can’t start.

Essential protective gear includes safety glasses, a push stick for keeping your fingers away from the blade during narrow cuts, and hearing protection. Table saws are not as loud as other woodworking machines, but you can still suffer long-term hearing loss after extended unprotected use.

Getting accidentally cut by a table saw is much less of a risk with a new breed of saw design. A company called Saw Stop is the inventor and leader in this area and offers models designed to instantly retract a spinning blade the moment it contacts flesh. You can see a test I did with a sausage on a Bosch that has similar technology on the video below. You simply cannot cut anything like meat with a saw of this type.

Watch the video below for a table saw safety lesson.

- Video Watch Time = 11 1/2 minutes

Understanding Kickback

Besides the potential hazard of cutting yourself, kickback is a main table saw hazard you need to guard against. It happens when the workpiece is grabbed by the blade and thrown back at the operator. The kickback risk can be almost eliminated so don’t let fear prevent you from using a table saw. Kickback typically happens in two ways:

- Wood gets pinched between the rip fence and the saw blade, causing the wood to lift and be propelled up and towards you by the spinning teeth.

- The saw blade binds or stalls in a misaligned or warped piece of wood, transferring the blade’s energy to the workpiece and sending it flying towards you.

There are table saw features that can greatly reduce the chance of kickback. One is called a riving knife. That’s what you see above, to the left of the blade. This thin piece of metal sits behind the blade and prevents the wood from pinching the blade’s sides. If the wood can’t get pinched by the saw blade, one type of kickback cannot occur. Riving knives are typically found on many modern table saws, and are similar to an older item called a splitter. This is also a thin piece of metal that prevents blade pinching, but splitters also typically have swivelling teeth that allow the wood to travel across the saw in only one direction. As an added layer of safety, stand to one side of the blade every time you make a cut.

Table saws offer one powerful way to boost your woodworking game, and they’re one of those things that you’ll probably use more than you imagine. Choose well and follow safety procedures and you’ll make great things happen at your place.