Stucco is a classic exterior wall treatment that’s being replaced by systems that look identical but perform much better. Typically and generically called “exterior insulation and finishing system” or EIFS (pronounced “eefs”), these modern stucco systems are made by different companies using the same basic approach. Rigid sheets of insulating foam is fastened to exterior walls, then troweled over with synthetic mixes that look like mortar but offer benefits that traditional stuccos can’t match. If classic stucco is part of the look you’re after for your new home or addition, EIFS is a technology you should definitely know about.

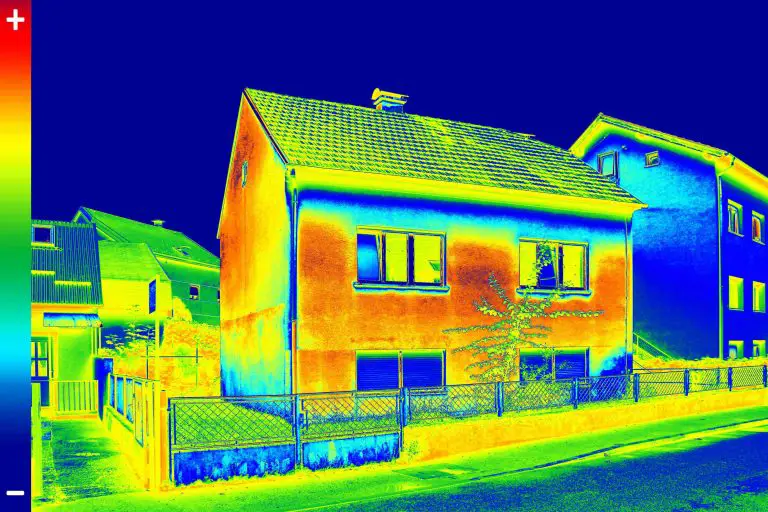

All buildings expand and contract with changes in temperature, and stucco needs to move with these changes if it’s to resist cracking and keep water out. This is crucial, and the main difference between traditional, crack-prone cement-based stuccos and today’s high performance EIFS polymer stuccos is flexibility. And there’s nothing like an extreme example to prove the point.

Although polymer stuccos are never applied to plastic sheets in the field, this exercise is useful because it shows just how flexible and sticky modern stuccos are. Once the stucco is cured, you can bend the sheet any way you want without cracks or separation. That’s what you can see below. If it weren’t for these remarkable qualities, the incredible weather resistance of EIFS wouldn’t exist.

Regardless of the EIFS involved, all use insulating foam sheets fastened to the outside surface of wall frames, using either trowel-applied adhesive or mechanical fasteners. Expanded polystyrene is the usual type of foam used. It’s white, beady sheets. Next, a layer of woven fiberglass reinforcing mesh is applied to the outside surface of the foam, held in place within a coat of trowel-applied adhesive. This is called the base coat, and it’s crucial because it adds impact strength to the completed system. Without mesh, EIFS wall surfaces would be too soft to be durable. Different weights of mesh offer more or less strength, depending on the application. All types of mesh can be cut with a utility knife or scissors on site. Even with the mesh in place, however, EIFS surfaces are softer and more damage prone than some other exterior wall surfaces. This is a drawback you should know about.

The topcoat of synthetic stucco comes next. It goes over the base coat and is that part of the EIFS system that remains visible. That’s why it comes in different colours and textures. Coarser or finer aggregates within the topcoat create different looks, depending on how the topcoat is troweled. You can also choose multi-colored aggregates within the topcoat that create a granite look. Some mixtures have actual stone chips embedded in the mix. Fine-grained topcoats are also sometimes applied by spraying instead of troweling, for added efficiency.

Since EIFS are a complete exterior wall system, various brands include factory-made trim, moulding and accessory components for use around windows, doors and other areas that need to go beyond just flat walls. This offers the chance to incorporate fancy design features that couldn’t otherwise be completed on site, while also speeding the installation process and reducing the skills required for success.

Besides durability and good looks, EIFS saves energy, too. Since the insulating foam layer that forms the foundation of the system extends across studs, plates and rough window frames, it stops the thermal bridging that plagues ordinary stud frame walls that have no continuous layer of exterior insulation. Roughly 25% of frame walls are made with wood that extends directly from interior to exterior surfaces, so it pays to work exterior foam into your designs to stop this thermal bridging.

Traditional stucco has never offered the reliability and visual options that EIFS does. That was okay when all buildings were leaky and drafty and well able to let leaked water dry out. Today we expect more from out buildings. EIFS is just one example of a revolution in building technologies that deliver greater durability and less maintenance, making it possible to build better than ever, and have homes last better than ever.