If you’re planning to build a new backyard deck this year (or refurbish an old one with a good frame but rotted top), you’re probably about to make a mistake. Several mistakes, actually. The reason is because standard deck building practice is surprisingly far from ideal in several key areas. Even professional builders regularly get things much less than ideal, leading to decks that could look better and could last much longer than they do.

The often-overlooked points I’ll share here come from my online course HOW TO BUILD A DECK. It covers all the key points I’ve been teaching people about deck construction and finishing since the 1990s. I’ve been refining this course since I first launched it in 2007, and I’ve put it on a $30-off special this spring. Use BONUS30 coupon code at checkout. Course participants get lifetime access to the course materials and updates, and full access to me for one-on-one consultations about making an optimal deck. Here’s where so many new decks fall short . . .

Deck Mistake#1: Failure to Promote Rot Resistance

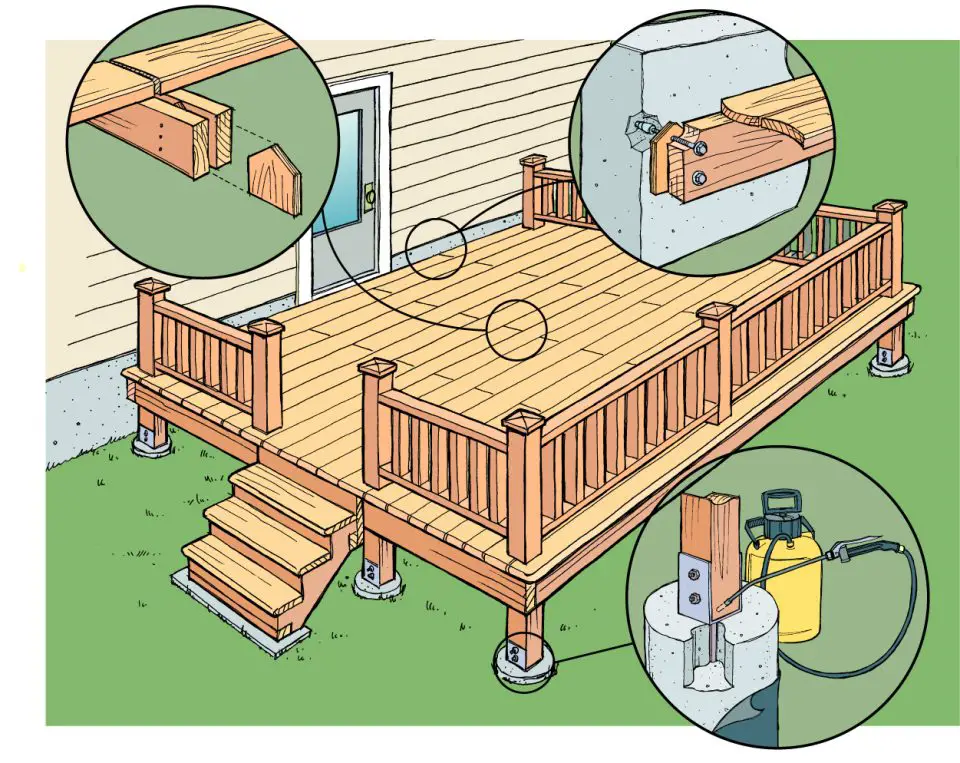

Too many people put too much faith in the rot resistance of “rot resistant” woods such as pressure treated, cedar or one of the tropical hardwoods used for deck building these days. Technically speaking, these woods are more rot resistant than other species, but that doesn’t make them rot resistant enough for a deck. At least not without some help in the form of what I call “moisture consciousness”.

Moisture consciousness is a way of looking at deck design so as to minimize wood-to-wood contrat areas that hold moisture. Wood requires moisture for rot processes to begin, so the better drained your can make your deck frame the longer it will last. How much of a difference does this make? Night and day, as a “tale of two deck” I know can show.

A friend of mine has a deck that’s part of a lovely log home he had built by a lake a few miles from my house. That was about 10 years ago, and today the cedar deck is already punky, soft, squishy and in need of replacement. Like so many decks, this one wasn’t built with wood-to-wood contact areas minimized, so rot-promoting water was held in joint areas that are now falling apart because of rot. Compare this to the deck I build at my house in 1998. It’s as sound and rot-free as the day I put it up. It doesn’t cost any more to build in a way that encourages the deck frame to dry out quickly, it just takes a realization of how important this is.

Deck Mistake#2: Failure to Apply Decorative Details

Decks are built with lumber that looks quite plain, and this means a certain level of plainness usually shows up in completed decks. The thing is, your deck can look so much nicer, and all it takes is a little work with a router. A router is a high-speed electric motor with handles. Routers spin cutting bits that can shape wood in different ways, and this is especially useful (and so frequently overlooked) with decks. I apply routed details in three simple ways and it makes a huge improvement in appearance.

Rounding over deck board overhang: By routing the overhanging edges of deck boards to a semi-circular profile it looks so much better than the simple, square-edged factory profile. You can see what I mean below. The profile wa created with two passes from a 3/4″ radius roundover bit, one pass on each face.

Chamfering vertical post corners: “Chamfer” describes an angled profile applied to otherwise square edges, and a large chamfering router bit will find lots to do on a deck. You can see these chamfers in action below.

Chamfering/rounding over deck board edges: This is a small detail, but it sure makes a deck look better. Applying a chamfer creates a more subtle effect than rounding over deck board edges, as you can see below.

Deck Mistake#3: Failure to Finish Properly

Disappointing deck finishes are the most frequent story of trouble I hear from deck owners, and the problem has several roots:

Bad deck finish choice: Many deck finishes and stains won’t last more than a year or two even if they are applied properly because they’re not up to the job. Bad chemistry is less of a problem than it used to be, but still an annoying source of disappointment. I’ve been testing deck finishes since 1990, and I can tell you that some products are just bad from the start.

Inadequate finish preparations: Even the longest lasting, most beautiful deck finishes last only half as long as they could if the deck surface is not prepared properly. The problem is that preparation can take a long time – in some cases even more time than applying the deck finish. The approach I find works best involves pressure washing, letting the deck dry completely, followed by sanding.

Unrealistic expectations: No matter how you slice it, maintaining a refined finish on a wooden deck is a lot of ongoing work. It’s the single biggest outdoor maintenance task except possibly for keeping your grass cut. This is why more and more people are using composite deck materials for the walking surface of their new or refurbished deck, rather than traditional solid lumber.

For the cost of less than half a dozen deck boards you can have all the deck building wisdom I’ve discovered since 1990. My course HOW TO BUILD A DECK is not about building a particular design of deck, but an approach for making any deck design longer lasting, more beautiful and less of a maintenance hassle. Click below to begin the course whenever you want and you can proceed at your own pace. My money-back guarantee makes it risk-free for you.