UPDATED 26Sep2020 + video below: There are tricks that make a big difference to the visual success of outdoor woodworking projects, and that’s what you’ll learn about here. You’ll find them useful for almost every project involving big, exterior wood. Decks, docks, gazebos, swing sets, mailbox posts and bird feeder stands. They’ll all be better for what you learn here.

Outdoor Projects Trick#1: Setting Posts

Whenever possible, it’s best to set posts directly into the soil without concrete. Why? Bare posts resist rot better than those set in concrete. Soil-set posts are also less likely to heave upwards with frost. The only exception to this is when a post needs to withstand significant sideways pressures without support from neighbouring posts or structures. That’s what you see below.

Railing posts at the bottom of a set of deck stairs are one example where setting posts in concrete makes sense. Concrete is the only way to eliminate the loose soil that invariably surrounds soil-set posts. Some kinds of play sets with swings and climbing bars need concrete-enhanced posts, too. As long as the concrete is poured against undisturbed soil, it will support that post without any movement. Just be sure to dig the hole tapering slightly larger at the bottom than the top, to minimize the chance of frost movement. Also, don’t let a “muffin top” of concrete ooze out of the top of the hole, either. Frost loves to push upwards on this, ruining the accuracy of your post positioning.

Whenever you’re replacing soil around the outside of a concrete-free post, do it in stages, compacting that soil after every 6” to 8” of new stuff is added. With a post standing upright in the hole, add loose soil into the space around the post with your hands before tamping it down with the end of the sledge hammer handle. Try to keep the post plumb while you do this (or get a helper to), checking with a level after the first round of tamping is done. The little bit of soil now in place at the bottom of the hole at this stage won’t stop you from making corrections to the post orientation, so get things plumb before adding and tamping more soil. The higher you go, the less correction is possible, but that’s okay. You’ll never be far from perfectly plumb each time if you check and adjust after each tamping session. By the time you’re done, the post will be plumb and solid.

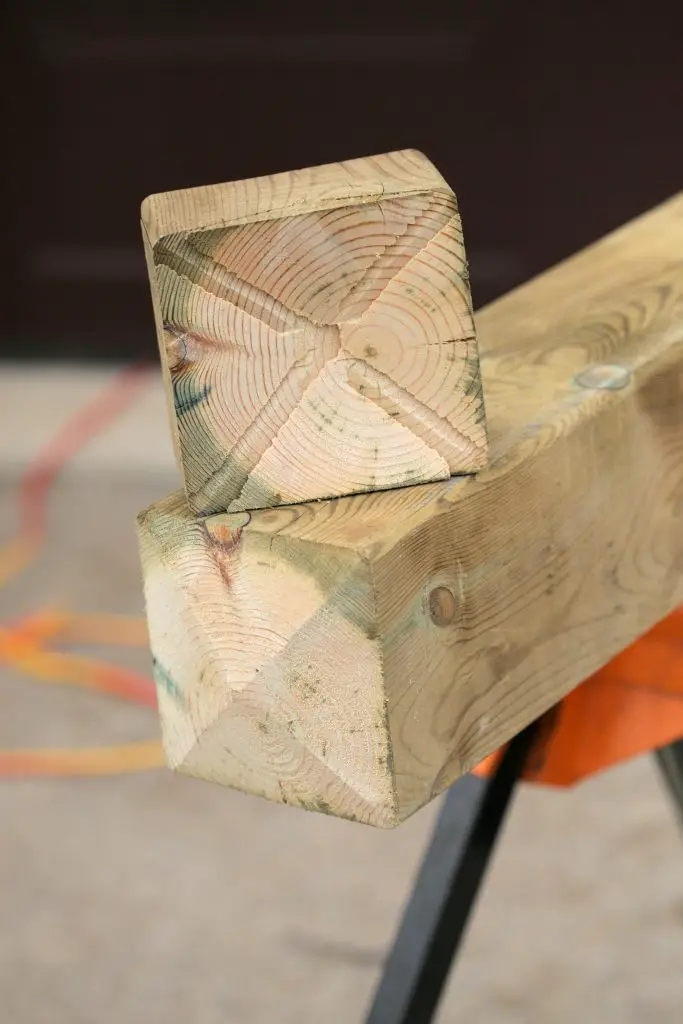

Outdoor Projects Trick#2: Make Pyramid End Cuts

I started adding this visual detail to the ends of 6×6 and 8×8 timbers about 25 years ago. You can see it in action on part of a mailbox post I built, shown above. The angle of the four cuts that create the pyramid isn’t critical, but I find that 15º from square looks ideal. Swivel the foot of your 7 1/4” circular saw to this angle, mark square lines around all four sides of a post, then follow up with four angled cuts.

The waste won’t fall off if you’re working with posts as big as 6x6s and 8x8s since standard saws don’t cut deep enough. That’s why you need to complete the cuts with a full-size handsaw (I prefer one with a Japanese tooth pattern) so the cuts meet at the pointed centre of the pyramid. There’s no need to saw all the way through. The sawn facets of the pyramid look rough at this stage, but it’s easy to refine them with an 80-grit abrasive in a belt sander. Precision is key. Keep the sander flat and steady, then work one facet at a time until they’re all smooth and come to a single point. The images below show the steps I use to make pyramid ends on 6×6 and 8×8 timbers. It’s simple, just expect the results to look a little rough until you use the belt sander.

Outdoor Projects Trick#3: Use a Level to Get Things Square

As the size of any outdoor project gets larger, hand-held squares become less and less useful. Even a small error with a square can mean a big mistake when assembly lengths are measured in feet, and this is where a level can help. Make big parts plumb or level and they’ll automatically be vertically square or parallel to each other. For parts that need to be leveled over distances longer than about 8 or 10 feet, a laser level or water level is more accurate. Check out the video below to see how a water level works. You’ll still need a square and pencil for laying out cuts and such, but levels make more sense when tasks get large.

Outdoor Projects Tip#4: How to Bore Big, Deep Holes

Big, long bolts are a key part of joining many outdoor projects, and installing them involves boring big, deep holes. This is where ship’s auger bits can help. Named after shipwrights who often had to drill large holes through thick wood, the name of the tool lives on even though ships today are made with plate steel and electric welders.

Although you won’t always need to drill 18”-deep holes, this is a good general purpose length to get. I use 1/2”, 3/4” and 1” bits most often for my outdoor projects. All ship’s augers are self-feeding, thanks to a steeply tapered screw at the tip. Although these bits will draw themselves into the wood without any help from you, they can be over-eager. Stop and reverse the bit after every 3” or 4” of drilling, to clear shavings from inside the hole. If you’ve got a lot of holes to drill beyond the reach of an extension cord, consider a gas-powered drill. They’re small, light and surprisingly powerful. Also, whenever you bore holes for carriage bolts, choose a bit that’s the same size as the bolt shank – no larger. You’ll need to hammer the bolt in, but that’s okay. The friction is useful for holding the bolt as you tighten the nut over a flat washer.

Big, outdoor wood projects don’t require the precision of fine furniture, but they do let you extend your craftsmanship in a way that you’ll see and use most every day of your outdoor life. Whenever I get the mail, fill up the bird feeder or see my wife, Mary, using the clothesline here at the end of Bailey Line Road, the trouble is more than worth it.

Click below for a video tour of some of the tips and tricks you’ve seen here.