Lucky Puck

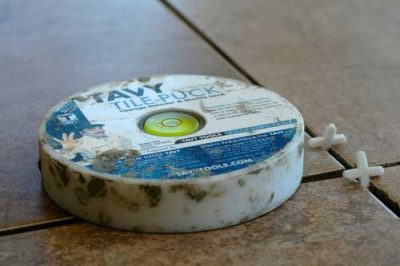

Fashions in the tile world are bringing larger and larger tiles to market, and these pose an installation challenge. The larger the tile the more challenging it is to lay it flat. That’s where a small, simple tool can help. Called an installation puck, it’s a dense, synthetic disk that makes a clicking sound when sliding over tiles with edges that don’t quite line up. This is faster and more reliable than working by eye and feel, and the tool includes a spirit bubble on top so you can monitor how level tiles are as they go down. There are two ways to make straight cuts in ceramic tiles: a diamond-tooth wet saw and a snap cutter.

Fashions in the tile world are bringing larger and larger tiles to market, and these pose an installation challenge. The larger the tile the more challenging it is to lay it flat. That’s where a small, simple tool can help. Called an installation puck, it’s a dense, synthetic disk that makes a clicking sound when sliding over tiles with edges that don’t quite line up. This is faster and more reliable than working by eye and feel, and the tool includes a spirit bubble on top so you can monitor how level tiles are as they go down. There are two ways to make straight cuts in ceramic tiles: a diamond-tooth wet saw and a snap cutter.

Diamond saws are precise, but they’re also noisy and cumbersome to set up. The best models are stationary machines that include water pumped onto the cutting zone to keep the blade clean and cool. Snap cutters operate on the same principle as a glass cutter. A hardened steel wheel scores the tile surface, then pressure is applied across the scored area causing the tile to snap. Scored cuts aren’t as predictable as sawn cuts, but a good quality unit that’s adjusted properly works very well. Regardless of the tool you use, cut edges are sharp and they look different than factory edges that are usually beveled or rounded, at least a little. You’ll need to re-establish this bevel if your cut tile edges will be placed anywhere other than the edge of a room, and a diamond block is an ideal tool for this job. Wet the pad with water, then rub it at a 45º angle across the outside corner of the sawn edge. In a minute or so you’ll create a nice bevel that matches factory edges surprisingly well.

Diamond saws are precise, but they’re also noisy and cumbersome to set up. The best models are stationary machines that include water pumped onto the cutting zone to keep the blade clean and cool. Snap cutters operate on the same principle as a glass cutter. A hardened steel wheel scores the tile surface, then pressure is applied across the scored area causing the tile to snap. Scored cuts aren’t as predictable as sawn cuts, but a good quality unit that’s adjusted properly works very well. Regardless of the tool you use, cut edges are sharp and they look different than factory edges that are usually beveled or rounded, at least a little. You’ll need to re-establish this bevel if your cut tile edges will be placed anywhere other than the edge of a room, and a diamond block is an ideal tool for this job. Wet the pad with water, then rub it at a 45º angle across the outside corner of the sawn edge. In a minute or so you’ll create a nice bevel that matches factory edges surprisingly well.

Reliable Wet Surface Installations

While many ceramic tiles are completely waterproof, not so the grout that fills the spaces between them. Even when grout is sealed, the effectiveness of the sealing action eventually wears off. This is why you should never install ceramic tiles in wet locations without taking steps to make the entire installation waterproof. And this means more than just using green or blue water resistant drywall or underlay underneath the tiles. This advice applies to shower walls, bathroom floors, laundry rooms and entranceways.

While many ceramic tiles are completely waterproof, not so the grout that fills the spaces between them. Even when grout is sealed, the effectiveness of the sealing action eventually wears off. This is why you should never install ceramic tiles in wet locations without taking steps to make the entire installation waterproof. And this means more than just using green or blue water resistant drywall or underlay underneath the tiles. This advice applies to shower walls, bathroom floors, laundry rooms and entranceways.

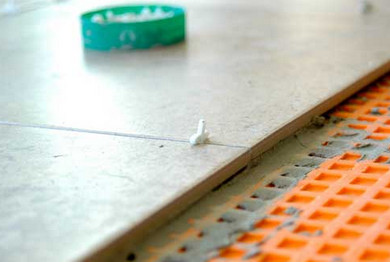

The best waterproofing strategies allow tile installations to harmlessly endure even standing water indefinitely, and waterproof underlay fabric makes it happen. Schluter’s KERDI was the first such product and it’s become the industry standard. Applied over a thin coat of thinset mortar, KERDI is much more waterproof than it appears to be. See for yourself by making a cone out of the material, then fill it with water. Even without sealing the joints, the fabric holds water surprisingly well. KERDI also comes in factory-formed corner pieces for creating a seamless waterproof membrane underneath all wet-area tiles.

The best waterproofing strategies allow tile installations to harmlessly endure even standing water indefinitely, and waterproof underlay fabric makes it happen. Schluter’s KERDI was the first such product and it’s become the industry standard. Applied over a thin coat of thinset mortar, KERDI is much more waterproof than it appears to be. See for yourself by making a cone out of the material, then fill it with water. Even without sealing the joints, the fabric holds water surprisingly well. KERDI also comes in factory-formed corner pieces for creating a seamless waterproof membrane underneath all wet-area tiles.