There are two ways to boost the insulation value of your home, the easy way and the hard way. The easy way uses fiberglass or cellulose fibres blown into the attic, an approach that’s used for most home insulation improvement campaigns in Canada. It’s fast, easy, highly effective and offers an excellent financial pay-back. You can blow insulation into walls too, but it’s almost never done because so few structures are candidates. You need large, completely hollow wall cavities with no existing insulation present. Upgrading the insulation in a 1000 sq.ft. attic should cost $700 to $1000, depending on its current state.

There are two ways to boost the insulation value of your home, the easy way and the hard way. The easy way uses fiberglass or cellulose fibres blown into the attic, an approach that’s used for most home insulation improvement campaigns in Canada. It’s fast, easy, highly effective and offers an excellent financial pay-back. You can blow insulation into walls too, but it’s almost never done because so few structures are candidates. You need large, completely hollow wall cavities with no existing insulation present. Upgrading the insulation in a 1000 sq.ft. attic should cost $700 to $1000, depending on its current state.

While boosting attic insulation is an excellent way to become a richer and more socially responsible homeowner, insulating walls deserves consideration, too. The trouble is, upgrading walls can be much more disruptive than attic work.

For jobs like this, few products are as useful and effective as rigid sheets of foam insulation. There are two main types, only one of which is appropriate:

- Beady white kind (called expanded polystyrene)

- Physically stronger blue or pink type (called extruded polystyrene)

Although both offer the same insulating value — R-5 per inch — the more expensive extruded version is better because of its higher density, strength and water resistance. Applied to the outside face of exterior walls as part of a re-siding job, or inside under a new layer of drywall, foam does an amazing job because of its unique ability to create an unbroken layer of insulation. Even if you’re planning an addition to your house, and will be using batts between the new wall studs, consider a layer of rigid foam in the mix. It bridges the insulation gaps that occur wherever a wall stud exists, boosting thermal performance more than you might think.

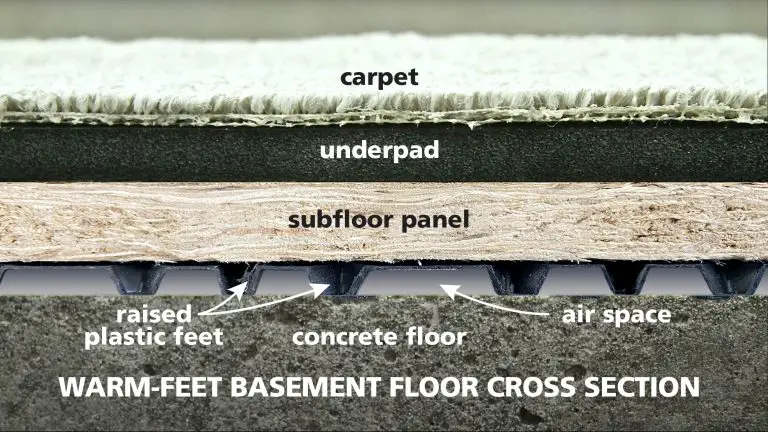

Got a cold floor? Consider the insulation sandwich. A layer of extruded polystyrene foam laid down on your old floor, under a new 1/2-inch plywood subfloor, is an easy way to make your toes toasty. And if you’re putting down a new finished floor anyway, it’s not a lot of trouble. Extruded polystyrene foam is dense enough that strapping is unnecessary. Simply drive screws through the new ply and the foam, extending at least 1 1/2-inches into the underlying floor joists.

Later this year I’ll be installing using Barricade Wall Panels for insulating a floor. I’ll tell you how it goes after the job is done.