Question: What should I put on the interior walls of a garage I’m converting to a workshop? I’ve kicked the car out and two of the walls are currently covered with OSB. Should I cover the remaining walls in OSB or drywall? I’m concerned about mold and deterioration if it gets damp in the garage.

Answer: That sounds like a good plan you’ve got going. A workshop is better than a garage any day, right? Workshops have walls covered in all sorts of materials, but drywall and OSB aren’t ideal in my experience. Drywall is pretty fragile, and OSB looks cheap even when painted. It’s also flammable and not particularly waterproof. Either material will work for your workshop, but the best option I’ve seen for a shop is metal roofing applied to interior walls.

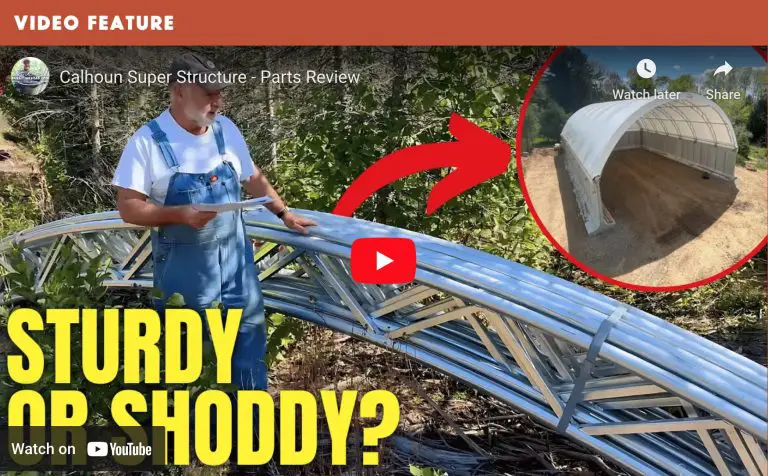

You order pieces in the lengths you need and fasten them with the usual roofing screws. Orient the pieces up-and-down. What you get is a tough, waterproof, fire-resistant surface that looks great while never needing to be finished. And if you sheath the walls in OSB or plywood before the metal goes on, you’ll be able to anchor most things anywhere you want in the wall since there’s a solid foundation everywhere for screws. The workshop in the photo above has metal roofing on the walls and it performs very well. Here’s a little tip about workshop moisture, too . . .

If you live in a place that gets any kind of winter, the dampest time of the year for home workshops is spring. When warm, moist outside air enters the shop immediately after a cold snap, the surfaces in the garage are still cold enough to cause condensation when the warmer air hits them from the outside. A little bit of heat in the garage during these times will stop your tools and equipment from rusting. It makes all the difference.

Will you be doing any woodworking in your new workshop space? Click here to learn about the dust collection system I installed in my own shop. It’s very nice not to have to eat dust every time I do some woodworking.