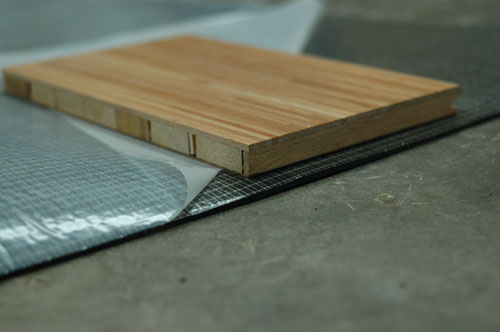

Until recently, all true wood floors involved either nailing or click-together edges, but a product called Elastilon (elastilon.org; 877.526.9663) has changed that in a way that I didn’t think possible. It’s a 3mm-thick, adhesive-backed foam underlay, and it secures many kinds of flooring independently of the subfloor. Besides speeding up installation by eliminating the need for nailing or clicking, the adhesive feature offers several other unique benefits that lead to better floor performance.

Lay Elastilon down on the subfloor, assemble pieces of wood flooring on top, then slide the backing layer off from underneath. This allows the adhesive and the flooring to come together and bond, anchoring everything tightly. That’s the installation process in a nutshell, but can you really trust peel-and-stick adhesive to secure a floor? That’s the question I set out to answer.

Elastilon is made by a Dutch firm and has been used in Europe for more than a decade, but when I first discovered it a year ago my biggest concern was how well it sticks. If you’re relying on adhesive alone to anchor oak or maple or tropical hardwood floor boards, it better be reliable. Without nails, adhesive is all you’ve got.

An Elastilon floor installation begins by cutting a length of product off the roll so it’s one board width plus 10cm longer than your room. Lay pieces of Elastilon down on the floor peelable side up, then peel the backing off of only the excess product that runs up the wall. This creates a flap of backing to grab onto and pull from underneath floor boards once they are in place. Place a row or two of floor boards side-by-side tightly on the floor, peel backing out from underneath, then install more boards and peel again until the room is done.

I know from my time working with Elastilon that it holds flooring very securely. Initial gluing strength is good, but not great. However, the boards become much more firmly stuck after an hour. How well this happy condition continues five, ten or fifteen years down the road, I can’t yet say. What I do know is that the only criticisms I’ve discovered about the product’s long-term use in Europe are related to uneven subfloors that allow floor boards to move enough to make noise underfoot. That said, uneven subfloors also cause problems with other kinds of wood floor installation methods, too. For what it’s worth, Elastilon does carry a 70-year limited warranty.

I know from my time working with Elastilon that it holds flooring very securely. Initial gluing strength is good, but not great. However, the boards become much more firmly stuck after an hour. How well this happy condition continues five, ten or fifteen years down the road, I can’t yet say. What I do know is that the only criticisms I’ve discovered about the product’s long-term use in Europe are related to uneven subfloors that allow floor boards to move enough to make noise underfoot. That said, uneven subfloors also cause problems with other kinds of wood floor installation methods, too. For what it’s worth, Elastilon does carry a 70-year limited warranty.

At $2/square foot, Elastilon isn’t cheap. But if you’re comparing it to the wages of a professional flooring installer fooling around with nails or glue, then the product price becomes more reasonable. In fact, Elastilon might even save you money. Product claims mention a 70% increase in installation speed, and from what I’ve seen this isn’t an exaggeration.

Apart from installation efficiency, Elastilon offers two unique technical advantages. First, since it makes all floors float, it eliminates the board-to-board gaps that typically develop seasonally in hardwood here in Canada. All expansion and contraction of floor boards as we move from dry winter conditions to moist summer air happens at the edges of the floors, not between each board. Also, the elimination of nails allows hardwood to be installed more easily and safely over radiant infloor heating systems, both above wooden subfloors and concrete.

Elastilon will probably come to be seen as a big innovation in the flooring world after initial skepticism wears off, and it probably won’t be the last product of its kind. I’ve often noticed how good ideas bring on plenty of imitators, especially when the concept has something to offer.