Perimeter Basement Wall Best Practices

Finishing a basement usually involves building finished wall surfaces to cover the inside face of exterior foundation walls of your house. The business of creating these finished walls is one of the places where the most serious basement finishing mistakes are made. Interior basement partition walls are different and less susceptible to moisture. I’ll get to those later. Below you’ll find a description of the five main approaches to creating finished walls around the exterior of a basement. Some of these approaches are good and I recommend them. Others should be avoided.

Before you go on, be sure to watch the video up next. It explains how to deal with the presence of “builders’ insulation” blankets – a common stumbling block many people encounter right up front with homes and basements built in the last 20 years, especially those found in cold climates.

VIDEO: Dealing With Builders’ Insulation on Basement Walls

Foam on Foundation Option

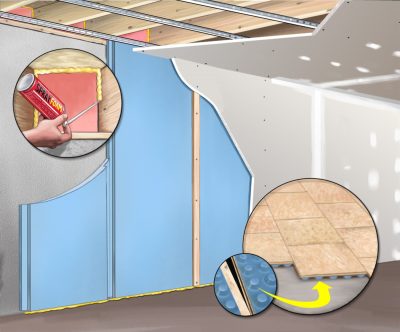

This is an excellent choice for perimeter wall treatment because it resists moisture so well. Rigid pieces of foam are held directly against the foundation wall in some way, often with strips of wood oriented vertically to hold the foam to the wall. Dow Wallmate is the most popular version of this kind of foam, though other companies make it, too. The foam comes in 8-foot lengths, 24” wide with grooves along each long side. When the groove of one piece of foam butts against the groove on another panel, the two make a groove just right for 1×3 wooden strips. This wood fastens to the underlying masonry with special screws that grip directly into concrete in predrilled holes. This wood holds the foam to the wall while also providing a surface later for securing drywall with screws. Click the video up next to learn more about the foam-on-foundation wall option.

VIDEO: The Foam-on-Foundation Option

Free-Standing Foam Panels

This is my favourite approach because it’s the most immune to moisture damage and mold. A strong, free-standing foam-core wall panel sits just inside the foundation perimeter wall without touching it. Each panel is anchored at the top and bottom to wooden strips, but there’s a gap between the back face of the panel and the foundation wall. These panels come from the factory with ready-to-finish drywall on the inside face. DRIcore makes the best freestanding basement panels that I know of right now. They’re called SMARTWALL. Besides great thermal performance, free-standing basement foam panels aren’t affected nearly as much by moisture, in part because they don’t touch basement floors or walls.

Click the video below to learn more about the free-standing foam wall option in the context of building a mold-resistant basement. I made this video a few years ago, but it’s still completely applicable and provides a good overview.

VIDEO: FREE-STANDING FOAM PANELS

Metal Stud Frame Wall with Spray Foam

Although this method uses studs, there are two reasons it’s a reasonable approach for perimeter walls. First, the metal studs don’t provide food for microbes because metal isn’t organic. Second, as long as closed cell spray foam is used to insulate and seal the space between metal studs, it’s impervious to the movement of water vapour. Polyurethane foam is the most common type of spray foam and it’s a good choice here. It’s closed cell (some foams are open cell – don’t use these in your basement) and layers 3” thick are sufficient to stop the movement of air and water vapour. This much closed cell foam is sufficient to act as it’s own vapour barrier, even in the coldest climates.

If you want a super-insulated basement, metal stud frame perimeter walls let you make that happen. If you fasten 2” of extruded polystyrene foam directly against the perimeter wall (as you read about in the foam on foundation section), then build a metal stud frame wall inside this with 3” of spray foam, you’ll have at least R25 of insulation. That’s enough for any basement in any climate, no matter how cold. Click the video below to learn more about the difference between closed cell and open cell spray foam. In most cases closed cell is the best stuff to use for basements, but you really should understand why. The video coming up next explains the details of spray foams as they apply to home building in general.

VIDEO: Spray Foam Insulation Basics

Wooden Stud Frame Wall with Spray Foam

Things could be worse than this choice, but the presence of wood as part of a perimeter wall poses unnecessary risk. Filling wall cavities with closed cell spray foam is good, but why introduce wood if it can be avoided? The less organic matter you have in your basement, the less potential microbe food exists if unexpected moisture enters the scene. I recommend against wood stud frames as part of all basement perimeter walls, though wood is fine for partition walls, as you’ll see. They’re not exposed to a moisture hazard if built correctly.

Quick Definition: “Joist”

Horizontal lengths of lumber installed on their edge to create a floor or ceiling support frame. Typical floor joists range from 2×8 to 2×12 lumber, or they can be made from engineered wood or wood/metal products. The floor joists that support the first floor of your home also act as the ceiling joists of your basement space.

Rim Joist Areas

The details here are key. Regardless of the perimeter basement wall system you choose, you’ll face the challenge of insulating the space above the wall where the floor joists that form the upstairs floor meet the outside walls of your house. This is called the “rim joist” area, and it’s present in every basement in some form. In a very real sense, the rim joist region is part of the exterior walls of your finished basement, though it’s almost always insulated improperly, leading to mold growth.

The details here are key. Regardless of the perimeter basement wall system you choose, you’ll face the challenge of insulating the space above the wall where the floor joists that form the upstairs floor meet the outside walls of your house. This is called the “rim joist” area, and it’s present in every basement in some form. In a very real sense, the rim joist region is part of the exterior walls of your finished basement, though it’s almost always insulated improperly, leading to mold growth.

Click the video below to learn about one method for dealing properly with rim joist areas. This is a small zone in any house, but vitally important. There’s more about the topic of rim joist areas throughout the course.

VIDEO: Proper Rim Joist Insulation & Sealing

+++++++++++++++++

Quick Definition: “Fibre-Based Insulation”

Any kind of batt or loose-fill insulation fits into this category. Fiberglass, rockwool, cellulose, wool and cotton are all fibre-based products. Most residential insulation is made with some kind of fibres because it’s the cheapest option.

++++++++++++++++++

Wood/Metal Studs with Fibre-Based Insulation

This is still the most common finished basement wall strategy and it’s the riskiest. Under ideal conditions this kind of wall can work, but the slightest bit of moisture inside the wall cavities – either liquid or vapour – triggers mold and mildew growth. Part of the reason for this is the need to install a plastic vapour barrier on the inside face of the wall. This is necessary when using any kind of fibre-based insulation in cool and cold climates to stop wintertime condensation and mold growth within the insulation. The thing is, a vapour barrier also means the hollow wall cavity can’t dry out. Vulnerability to moisture is why I strongly recommend against framing perimeter basement walls with fibre-based insulation.

Click for a video tutorial explaining the unique dangers of frame walls and fiber-based insulation on exterior basement walls.